個(gè)人簡(jiǎn)介:

王燁����,工學(xué)博士,副教授���,博士生導(dǎo)師,美國(guó)TMS會(huì)員����,中國(guó)知網(wǎng)專(zhuān)家?guī)斐蓡T,四川省學(xué)術(shù)和技術(shù)帶頭人后備人選����,四川省科技專(zhuān)家?guī)斐蓡T。

Email:wangye@scu.edu.cn

四川大學(xué)望江校區(qū)beat365322室(610065)

四川大學(xué)江安校區(qū)基礎(chǔ)教學(xué)樓B109室(610225)

教育簡(jiǎn)歷:

2003.09-2007.07�����,昆明理工大學(xué)材料科學(xué)與工程專(zhuān)業(yè)����,獲得工學(xué)學(xué)士學(xué)位。

2007.09-2010.05�,昆明理工大學(xué)材料物理化學(xué)專(zhuān)業(yè),獲得工學(xué)碩士學(xué)位�。

2010.09-2015.09��,日本東京大學(xué)材料工學(xué)專(zhuān)業(yè),獲得博士學(xué)位�����。

2018.05-2020.04��,四川大學(xué)化學(xué)工程與工藝專(zhuān)業(yè)����,博士后出站。

工作簡(jiǎn)歷:

2015.10-2018.08��,beat365冶金工程系���,特聘副研究員���。

2018.09-今,beat365化學(xué)工程系����,副教授,碩士生導(dǎo)師���。

2022.08~2023.08��,江蘇省常州市新北區(qū)科技局副局長(zhǎng)��,掛職���。

主要研究領(lǐng)域:

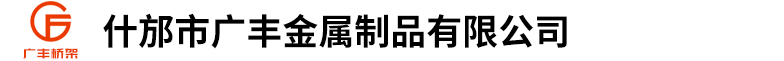

1.太陽(yáng)能級(jí)多晶硅電池制備與稀有金屬的分離提純:

利用冶金法選擇性高效去除多晶硅中雜質(zhì)����,低成本制備太陽(yáng)能級(jí)多晶硅����。應(yīng)用:多晶硅太陽(yáng)能電池

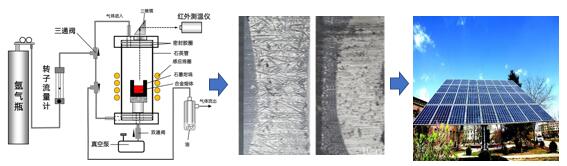

2.高熵合金制備及應(yīng)用

通過(guò)成分和工藝調(diào)控,制備兼具高強(qiáng)度和高韌性的超性能高熵合金材料����。應(yīng)用:航空航天、機(jī)械關(guān)鍵零部件��、涂層等�����。

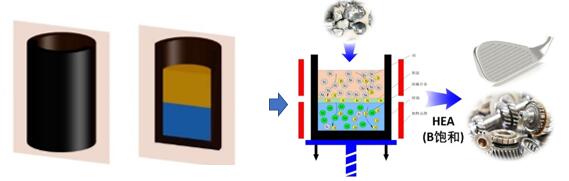

3.工業(yè)副產(chǎn)物的高值循環(huán)利用

針對(duì)鈦石膏����、磷石膏�����、鈦白廢酸、赤泥等工業(yè)固廢帶來(lái)的環(huán)境問(wèn)題�,利用新型冶金、化工處理技術(shù)���,結(jié)合工業(yè)布局特點(diǎn)����,實(shí)現(xiàn)廢棄物的高值制備和元素的循環(huán)利用�����。

4.微米級(jí)大容量低成本硅基電池負(fù)極研發(fā)

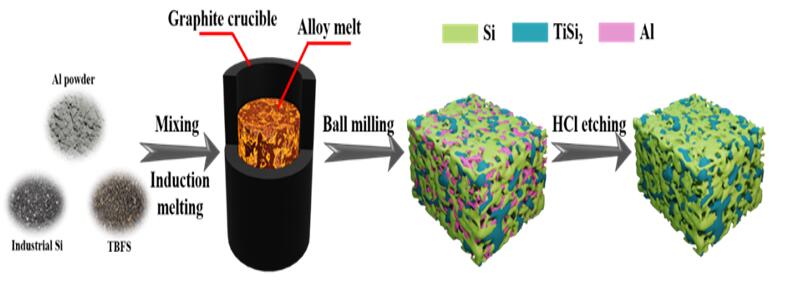

隨著電動(dòng)汽車(chē)和儲(chǔ)能系統(tǒng)的快速發(fā)展�,傳統(tǒng)電池負(fù)極材料,如石墨�,已經(jīng)無(wú)法滿(mǎn)足日益增長(zhǎng)的能量需求。硅作為一種具有高理論比容量的儲(chǔ)能材料備受關(guān)注���。項(xiàng)目提出利用廉價(jià)的含鈦高爐渣�����、切割硅廢料等作為原材料��,通過(guò)高溫可控反應(yīng)���、高能球磨���、噴霧干燥、定向刻蝕等技術(shù)制備出微米級(jí)硅基合金負(fù)極材料���。特殊結(jié)構(gòu)可以緩解硅在充放電過(guò)程中的體積膨脹問(wèn)題�,將為快充動(dòng)力汽車(chē)���、儲(chǔ)能系統(tǒng)等領(lǐng)域提供高性能的電池材料�,在環(huán)境保護(hù)和資源回收方面也具備潛在的經(jīng)濟(jì)和社會(huì)效益��。

5.工業(yè)設(shè)計(jì)與經(jīng)濟(jì)評(píng)價(jià)

主要工作業(yè)績(jī):

課題組以堅(jiān)持綠色環(huán)保發(fā)展和建設(shè)新能源新材料美麗世界為教學(xué)和科研理念�,主要從事于利用冶金法制備新能源材料、太陽(yáng)能級(jí)多晶硅造渣精煉�����、稀有金屬的分離提純及廢棄物循環(huán)利用回收等領(lǐng)域的研究�,迄今在Carbon, ACS Applied Materials and Interfaces, Inorganic Chemistry, Journal of Cleaner Production, Industrial Engineering Chemical Research, Hydrometallurgy,Solar Energy and Solar Cells, Metallurgical and Material Transaction B等國(guó)際國(guó)內(nèi)高水平學(xué)術(shù)期刊及學(xué)術(shù)會(huì)議上發(fā)表論文40余篇����,授權(quán)中國(guó)發(fā)明專(zhuān)利8項(xiàng)�,項(xiàng)目經(jīng)費(fèi)400余萬(wàn)。

承擔(dān)項(xiàng)目情況:

項(xiàng)目類(lèi)別 |

批準(zhǔn)號(hào) |

項(xiàng)目名稱(chēng) |

起止年月 |

金額(萬(wàn)) |

項(xiàng)目狀態(tài) |

排名 情況 |

國(guó)家級(jí) |

22378272 |

利用高熵合金定向凝固去除硅廢料中硼雜質(zhì)的協(xié)同機(jī)制研究 |

2024.1-2027.12 |

50 |

在研 |

主持 |

國(guó)家級(jí) |

516041761003405 |

揮發(fā)性渣氣去除冶金級(jí)多晶硅中雜質(zhì)的物理化學(xué)研究 |

2017-2019 |

20 |

結(jié)題 |

主持 |

省級(jí) |

24GJHZ0432 |

微米級(jí)大容量低成本多孔硅鈦鋰電池負(fù)極研發(fā) |

2024.1-2025.12 |

20 |

在研 |

主持 |

省級(jí) |

2021YFH0131 |

高溫萃取法制備高純硅與高強(qiáng)度HEA機(jī)理與工藝研究 |

2021.4-2023.3 |

20 |

結(jié)題 |

主持 |

省級(jí) |

2018SZ0285 |

硫磺還原分解鈦白石膏制硫酸技術(shù)及硫鐵鈣資源循環(huán)利用 |

2017-2019 |

20 |

結(jié)題 |

主持 |

省級(jí) |

2019YFH0149 |

利用光伏硅廢棄物和高爐鈦渣合成TiSi2-Si鋰離子電池負(fù)極材料 |

2019-2021 |

30 |

結(jié)題 |

主研 |

市級(jí) |

2022-YF05-00265-SN |

用于降解VOCs的高熵合金納米催化劑研制 |

2023.6-2024.5 |

10 |

在研 |

主持 |

市級(jí) |

2016-HM01-00399-SF |

微波活化高爐渣礦化CO2 |

2017-2019 |

10 |

結(jié)題 |

主持 |

市級(jí) |

2018CDPZH-24 |

硫鐵礦(或硫磺)分解鈦白石膏及硫鐵鈣資源內(nèi)循環(huán)利用技術(shù) |

2018-2020 |

10 |

結(jié)題 |

主持 |

校級(jí) |

0030704153019 |

梯度燒結(jié)-納米微晶新型人工骨的構(gòu)筑及應(yīng)用研究 |

2020-2021 |

10 |

結(jié)題 |

主持 |

校級(jí) |

20822041A4028 |

利用揮發(fā)性渣精煉去除冶金級(jí)多晶硅中雜質(zhì)的物理化學(xué)研究 |

2015-2018 |

30 |

結(jié)題 |

主持 |

校級(jí) |

四川大學(xué)通識(shí)教育核心課程項(xiàng)目 |

《科學(xué)技術(shù)簡(jiǎn)史:從石器到量子》 |

2020-2021 |

20 |

結(jié)題 |

主持 |

校級(jí) |

研究生教學(xué)改革項(xiàng)目 |

面向新工科的泛在學(xué)習(xí)與多維度《技術(shù)經(jīng)濟(jì)學(xué)》課程教學(xué)改革探索 |

2018-2020 |

0.6 |

結(jié)題 |

主持 |

企業(yè) |

H240308 |

高鹽廢水資源化處理研究 |

2023.6-2025.12 |

300 |

在研 |

主持 |

企業(yè) |

21H0012 |

鈦石膏在建材中的應(yīng)用技術(shù)研究 |

2021.1-2023.1 |

100 |

結(jié)題 |

主持 |

政府 |

H230921 |

常州國(guó)家高新區(qū)合作咨詢(xún) |

2023.9-2025.8 |

20 |

在研 |

主持 |

政府 |

H211037 |

什邡市“十四五”能源與產(chǎn)業(yè)發(fā)展規(guī)劃編制 |

2021.10-2022.12 |

50 |

結(jié)題 |

主持 |

企業(yè) |

H230642 |

生物質(zhì)潤(rùn)滑油產(chǎn)學(xué)研合作 |

2023.6-2024.5 |

5 |

結(jié)題 |

主持 |

企業(yè) |

H230320 |

自清潔抗震材料研發(fā) |

2023.3-2024.3 |

5 |

結(jié)題 |

主持 |

國(guó)家級(jí) |

2017YFB0307504 |

低電耗電化學(xué)制氟及五氟化磷生產(chǎn)技術(shù)示范 |

2017-2020 |

205 |

結(jié)題 |

第四 |

國(guó)家級(jí) |

2016YFB0600904 |

CO2礦化非堿性礦的離子遷移規(guī)律及過(guò)程強(qiáng)化基礎(chǔ) |

2016-2021 |

904 |

結(jié)題 |

第十 |

研究成果:

論文(一作或通訊論文):

(1) Fan Gao, Dingyue Zhang, Hao Zhang, Caiqin Gao, Gang Huang, Ziqiang Zhang, Yong Liu, Ye Wang*, Mauricio Terrones, Yanqing Wang*. Liquid bath-assisted combustion activation preparation of nitrogen/sulfur-doped porous carbon for sodium-ion battery applications, Carbon, 2024, 229, 119481. https://doi.org/10.1016/j.carbon.2024.119481.

(2) Mouqiao Zheng, Qijie Yi, Ye Wang*, Wenxiang Tang*, Xiaodong Ma, Youngjae Kim. Engineering oxygen vacancies of Co-Mn-Ni-Fe-Al high-entropy spinel oxides by adjusting Co content for enhanced catalytic combustion of propane, Inorganic chemistry, 2024. https://pubs.acs.org/doi/10.1021/acs.inorgchem.4c02659.

(3) Jiangmei Yi, Shuai Li, Wenyu Yang, Yujunyao Wang, Hao Hu, Hua Meng, Ye Wang*. Study on strengthening the crystallization process of removing F and P from phosphogypsum produced by dihydrate–hemihydrate wet process. Metallurgical and Materials Transactions B, 2024. https://doi.org/10.1007/s11663-024-03151-w.

(4) Yong Liu, Yanjun Zhong, Zhihua Zeng, Pan Zhang, Hao Zhang, Ziqiang Zhang, Fan Gao, Xiaodong Ma, Mauricio Terrones, Ye Wang*, and Yanqing Wang*. Scalable Synthesis of a Porous Micro Si/Si-Ti Alloy Anode for Lithium-Ion Battery from Recovery of Titanium-Blast Furnace Slag. ACS Applied Materials & Interfaces, 2023 15 (47), 54539-54549�����,DOI: 10.1021/acsami.3c13643

(5) Yong Liu, Zhihua Zeng, Yanjun Zhong, Wenxiang Tang, Ye Wang*, Zhiyuan Chen, Wenhui Ma, Kazuki Morita. Mechanism study on a recyclable and clean process for boron removal from industrial-grade silicon using CrMnFeNiMe high-entropy alloy, Journal of Cleaner Production, 420 (2023): 138330. Web. https://doi.org/10.1016/j.jclepro.2023.138330.

(6) 向夢(mèng)琪���,孟華,王燁��,孟憲章���,白宇航�����,王余軍垚���,張譯丹. 鈦石膏中鐵浸出動(dòng)力學(xué)及其酸浸循環(huán)工藝研究[J]. 無(wú)機(jī)鹽工業(yè). 2023, doi:10.19964/j.issn.1006-4990.2023-0141.

(7) Qipeng Li, Cong Feng, Quanle Cao, Wei Wang, Zihan Ma, Yonghao Wu, Tinghan He, Yangtian Jing, Wenxuan Tan, Tongxiao Liao, Jie Xing, Xiangfeng Li, Ye Wang*, Yumei Xiao, Xiangdong Zhu, Xingdong Zhang, Strategies of strengthening mechanical properties in the osteoinductive calcium phosphate bioceramics, Regenerative Biomaterials, Volume 10, 2023, rbad013, https://doi.org/10.1093/rb/rbad013.

(8) 王燁,陳桂鑫�,徐玥瑤���,王冠智,張柏林. 多學(xué)科交叉通識(shí)教育對(duì)大學(xué)生創(chuàng)新能力影響的實(shí)證研究—以《科學(xué)技術(shù)簡(jiǎn)史:從石器到量子》通識(shí)課為例[J].中文科技期刊數(shù)據(jù)庫(kù)(全文版)教育科學(xué), 2023(3):6.

(9) Ye Wang, Genkuan Ren, Bing Jiang, Lin Yang, Zhiye Zhang, Xinlong Wang, Yanjun Zhong, Zhiyuan Chen, Xiushan Yang, Kazuki Morita, Wenhui Ma. Fabrication of a nanosize hematite pigment via waste ferrous sulfate recycling using sulfur reduction. Metallurgical and Material Transaction B 54, 22–28 (2023). https://doi.org/10.1007/s11663-022-02584-5.

(10) Mengqi Xiang, Zike Han, Ye Wang*, Wenxiang Tang, Zhiyuan Chen, Wenhui Ma, and Kazuki Morita, Novel CrFeCoNiSi6/Si system for boron removal from metallurgical silicon feedstock, Industrial & Engineering Chemistry Research, 2022, 61 (9), 3412-3417, DOI: 10.1021/acs.iecr.1c04930

(11) Zhihua Zeng, Ye Wang*, Junjie Shi, Shimiao Zhou, Wenxiang Tang, Zhiyuan Chen, Wenhui Ma, Danyang Li, Kazuki Morita, Enhanced boron removal by CrMnFeNi-based high-entropy alloys during purification of silicon, Separation and Purification Technology, 279, 2021, 119682, https://doi.org/10.1016/j.seppur.2021.119682.

(12) Zhihua Zeng, Mengqi Xiang, Dan Zhang, Junjie Shi, Wei Wang, Xiaopeng Tang, Wenxiang Tang, Ye Wang*, Xiaodong Ma, Zhiyuan Chen, Wenhui Ma, Kazuki Morita, Mechanical properties of Cantor alloys driven by additional elements: a review, Journal of Materials Research and Technology, 15, 2021, 1920-1934, https://doi.org/10.1016/j.jmrt.2021.09.019.

(13) Hui Chen, Xizhi Yuan, Kazuki Morita, Yanjun Zhong, Xiaodong Ma, Zhiyuan Chen, Ye Wang*. Reaction mechanism and kinetics of boron removal from molten silicon via CaO-SiO2-CaCl2 slag treatment and ammonia injection. Metallurgical and Material Transaction B 50, 2088–2094 (2019). https://doi.org/10.1007/s11663-019-01639-4

(14) Ye Wang, Fang Chen, Xiaodong Ma, Guoquan Zhang*, Recovery of nitric and acetic acids from etching waste solutions using a synergistic system consisting of N235 and TRPO in cyclohexane, Hydrometallurgy, 185, 2019, 23-29. https://doi.org/10.1016/j.hydromet.2019.01.015.

(15) Zike Han�����,Jianqiu Gao��,Xizhi Yuan��,Yanjun Zhong�,Xiaodong Ma,Zhiyuan Chen�����,Dongmei Luo�����,Ye Wang*. Microwave roasting of blast furnace slag for carbon dioxide mineralization and energy analysis[J]. RSC Advances, 10, 17836–17844. 10.1039/D0RA02846K.

(16) Ye Tao, Bin Jiang, Xiushan Yang, Xiaodong Ma, Zhiyuan Chen, Xinlong Wang, Ye Wang*, Physicochemical study of the sustainable preparation of nano-Fe2O3 from ferrous sulfate with coke. Journal of Cleaner Production, 255, 2020, 120175. https://doi.org/10.1016/j.jclepro.2020.120175.

(17) Hui Chen, Kazuki Morita, Xiaodong Ma, Zhiyuan Chen, Ye Wang*. Boron removal for solar-grade silicon production by metallurgical route: A review. Solar Energy Materials and Solar Cells, 2019(203), 110-169. https://doi.org/10.1016/j.solmat.2019.110169.

(18) 張雨露�����,王燁*,楊林���,楊秀山���,王辛龍. 硫磺分解氟石膏制高純氧化鈣聯(lián)產(chǎn)硫酸的研究, 無(wú)機(jī)鹽工業(yè), 2020(7): 70-73.

(19) 王燁,吉旭���,顧武安���,黃青松����,泛在學(xué)習(xí)在《技術(shù)經(jīng)濟(jì)學(xué)》新工科課程的教學(xué)實(shí)踐[J]. 教育現(xiàn)代化, 2020, 007(006):57-61. https://doi.org/10.1654/j.cnki.2095-8420.2020.06.021

(20) Ye Wang, Tianming Wan, Yanjun Zhong, Xiaodong Ma, Zhiyuan Chen, Xinlong Wang*. Environmental sustainability of renewable phosphogypsum by CaS - Characterization and process optimization. Journal of Thermal Analysis and Calorimetry. 139, 3457–3471 (2020), https://doi.org/10.1007/s10973-019-08718-3.

(21) Zhong Yanjun, Zheng Linxin, Wu Zhenguo, Guo Xiaodong, Wang Xinlong, Wang Ye*, & Zhong Benhe. (2019). Microwave-assisted rheological phase synthesis of LiFe0.5Mn0.3Co0.2PO4 /C cathode materials for lithium ion batteries. Materials Research Express, 6(3), 035003, https://doi.org/10.1088/2053-1591/aaf30c.

(22) 王燁, 王俊哲, 張志業(yè), et al. 不同氣氛對(duì)硫鐵礦與磷石膏反應(yīng)過(guò)程軟化溫度的影響研究[J]. 無(wú)機(jī)鹽工業(yè), 2017(12):57-60.

(23) Chen H, Wang Y*, Morita K. Model implementation of boron removal using CaCl2-CaO-SiO2 slag system for solar-grade silicon [J], Metallurgical and Material Transaction B, 48, 3219–3227 (2017). https://doi.org/10.1007/s11663-017-1105-7.

(24) 李如虎, 李春, 岳海榮, 梁斌, 呂莉,王燁*. 溫度制度對(duì)鉀長(zhǎng)石-硫酸鈣-碳體系焙燒提鉀��、還原脫硫以及CO2礦化的影響����,化工礦物與加工,2017(4), 20-24.

(25) Ye Wang, Junzhe Wang, Zhiye Zhang, Lin Yang, Xiushan Yang, Benhe Zhong, Xingjian Kong, Xinlong Wang*. Investigation of the fusion characteristics of ash in the reduction of pyrite and phosphogypsum [J]. Journal of Sustainable Metallurgy, 3, 737–752 (2017). https://doi.org/10.1007/s40831-017-0138-0.

(26) Ye Wang, Kazuki Morita, Measurement of the phase diagram of the SiO2-CaCl2 system and liquid area study of the SiO2-CaO-CaCl2 system, Metallurgical and Materials Transactions B, 2016, 47(3):1542-1546.

(27) Ye Wang, Kazuki Morita, Measurement of CaO-SiO2-CaCl2 slag density by an improved Archimedean method�,Journal of Mining and Metallurgy. Section B: Metallurgy. 51 (2) B (2015) 113-116

(28) Ye Wang, Kazuki Morita, Reaction Mechanism and Kinetics of Boron Removal from Molten Silicon by CaO-SiO2-CaCl2 Slag Treatment [J]. Journal of Sustainable Metallurgy, 2015, 1(2):126-133.

(29) Ye Wang, Xiaodong Ma, Kazuki Morita. Evaporation Removal of Boron from Metallurgical-Grade Silicon Using CaO-CaCl2-SiO2 Slag [J]. Metallurgical and Materials Transactions B, 2014, 45(2):334-337.

(30) Ye Wang, Wenhui Ma, Jijun Wu, Yang Zhou, Bin Yang, Yongnian Dai, Morita Kazuki. Research on boron removal of metallurgical grade silicon with silica by ozidizing refining[C]// China-russia Symposium on Advanced Materials & Technologies. 2009.

(31) 王燁, 伍繼君, 馬文會(huì), et al. 太陽(yáng)能級(jí)硅制備技術(shù)與除硼工藝研究現(xiàn)狀[C]// 全國(guó)冶金物理化學(xué)學(xué)術(shù)會(huì)議. 2008.

(32) 王燁, 李秋霞, 楊斌, et al. 真空下低價(jià)氯化鋁生成及其分解熱力學(xué)簡(jiǎn)化研究[J]. 真空, 2009, 46(4):61-65.

授權(quán)發(fā)明專(zhuān)利

(1)王燁,楊貴翔����,韓子柯�����,任永生�,王辛龍�,利用高熵合金提純多晶硅的方法,ZL 2019102582211.1

(2)王燁��,韓子柯��,陳輝�����,袁熙志�,楊林,鐘艷君�����,許德華�,王辛龍,微波活化高爐渣的方法��,ZL2018110878754。

(3)王燁�����,李朝榮�,楊林,凌浩瀚��;鐘艷君���;王辛龍�����,制氟陽(yáng)極及其制備方法,ZL2018111355335�����。

(4)王燁�����,張雨露�,楊林,凌浩瀚,鐘艷君���,王辛龍�,改善制氟陽(yáng)極性能的方法��,ZL201811135532.0

(5)王燁���,陳輝�����,袁熙志��,王辛龍����,一種揮發(fā)性渣氣協(xié)同提純多晶硅的方法���,ZL201810272495.1��。

(6)伍繼君���,馬文會(huì)�,王燁等�����,一種硅中硼雜質(zhì)的去除方法�����,ZL200910094519.X�����。

(7)王燁�����,曾治華�����,張雨露�����,楊林���,楊秀山�,陶冶�,王辛龍,一種利用鈦石膏制備氧化鈣并聯(lián)產(chǎn)硫酸的方法���,ZL201911200030.6�����。

(8)王燁��,劉勇�����,向夢(mèng)琪�,李琪鵬等���,一種低碳型超硫酸鹽水泥及其制備方法�,以及水泥砂漿���,ZL202110834212.X���。

實(shí)驗(yàn)設(shè)備

實(shí)驗(yàn)室優(yōu)秀學(xué)生

研究生團(tuán)隊(duì)

實(shí)驗(yàn)室生活

招生專(zhuān)業(yè):

化學(xué)工程與工藝�,化學(xué)冶金和材料技術(shù)等相關(guān)專(zhuān)業(yè)